New DF-8 Enameled Wire Electric Paint Squeegee 110 / 220V Handheld Scraper 0.3-3.0mm Peeler EU US pulg Lacquer peeler | Инструменты

Сохраните в закладки:

История цены

*История изменения цены! Указанная стоимость возможно, уже изменилось. Проверить текущую цену - >

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-16-2025 | 5698.63 руб. | 5812.11 руб. | 5755 руб. |

| Jul-16-2025 | 4622.15 руб. | 4714.19 руб. | 4668 руб. |

| Jun-16-2025 | 5609.87 руб. | 5721.96 руб. | 5665 руб. |

| May-16-2025 | 5564.22 руб. | 5675.71 руб. | 5619.5 руб. |

| Apr-16-2025 | 4442.85 руб. | 4531.60 руб. | 4486.5 руб. |

| Mar-16-2025 | 5474.88 руб. | 5583.16 руб. | 5528.5 руб. |

| Feb-16-2025 | 5429.48 руб. | 5538.54 руб. | 5483.5 руб. |

| Jan-16-2025 | 5384.9 руб. | 5492.4 руб. | 5438 руб. |

Новые товары

Комбинированные кусачки Jetech 1 шт. 6 дюймов, 7 дюймов и 8 дюймов с высокой рычажной силой, удобной рукояткой, термообработанной стали и пожизненной гарантией.

Инструмент для вытаскивания разъемов и зажимов оптоволоконных коннекторов IET Pilers Room Tools Stripper on.

Инструмент для соединения фитинга и ПВХ трубы FT-1225.

Многофункциональный инструмент для обжима кристаллических коннекторов с ручным механизмом для сетевых кабелей RJ-11 / RJ-12 RJ-45 на 4P 6P 8P.

Профессиональный компрессионный инструмент типа F-головки для зажима разъемов RG6 RG59 RG11.

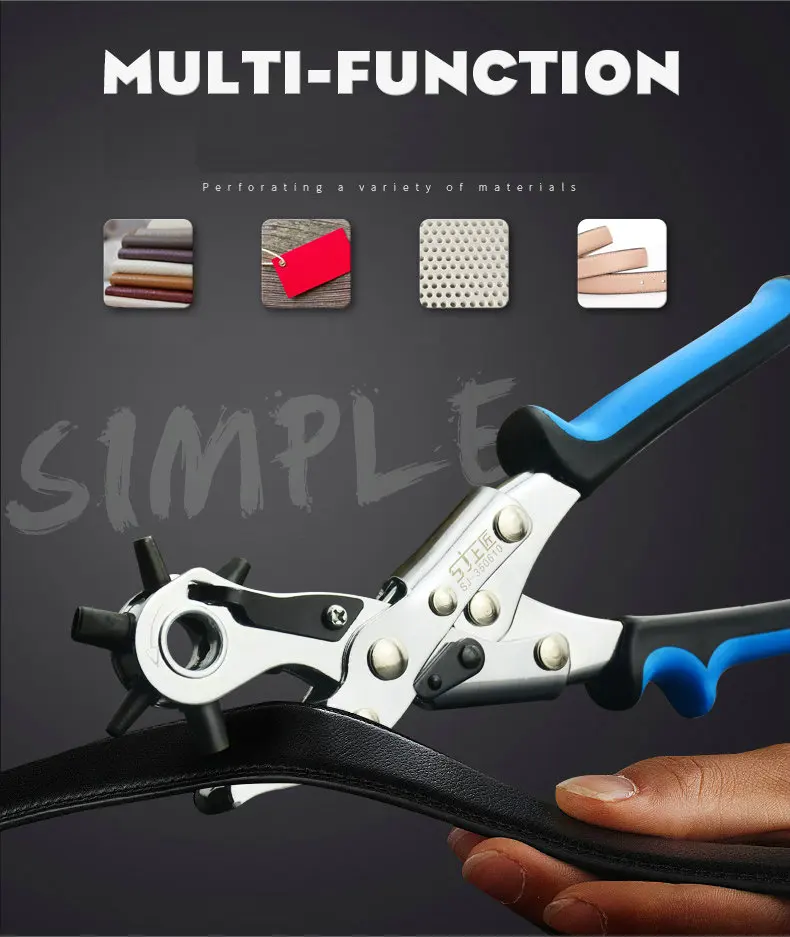

Плоскогубцы с 6 отверстиями для многоразового использования для прокалывания кожи, пластика, отверстий для часовых ремешков. Круглая/формованная опция. Бесплатная доставка.

Мини щипцы для кассеты кристаллизации, используемые для плавления и отливки на графитовой печи, держатель ложки.

Комплект терминалов JST-PH SN-28B 460 с разъемом для женских контактов на шаге 2,0 мм и адаптерами корпуса PH - 2/3/4/5/6 для подключения кабелей.

Характеристики

New DF-8 Enameled Wire Electric Paint Squeegee 110 / 220V Handheld Scraper 0.3-3.0mm Peeler EU US pulg Lacquer peeler | Инструменты

Описание товара

110V/220V Enameled Wire Stripping Machine, Varnished Wire Stripper, Enameled Copper Wire Stripper DF-8

1、cooling function

2、swich button

3、Adjustable speed

Трекер стоимости

Отзывы покупателей

Новые отзывы о товарах

Здравствуйте . есть у вас 4 шт. ? ... Читать отзыв полностью...

Не прислали товар,вышли все сроки и обманули с возвратом денег.Аферисты,не связывайтесь с ними....... Читать отзыв полностью...

Direct 7 day delivery store этот магазин афериста и жуликов не ведитесь на дешёвые товары, обманут и деньги не вернули.... Читать отзыв полностью...

Эта очень хитрая воровка Не связывайтесь Товар получите не тот что заказывали Или брак-востановлению не подлежит Спор открыть она вам... Читать отзыв полностью...

Очень рекомендую товар этого продавца, я купил гобелен Тайный ужин, имитация жаккардового эффекта, очень-очень красивая, очень-очень хорошая цена, и цена... Читать отзыв полностью...

Мошенники, кидают людей,при покупке ключа он обязательно уже не рабочий ,осторожно, не ведитесь !!!!!!!!!!!!!... Читать отзыв полностью...