Трехфазный асинхронный двигатель мягкий стартер управления напряжением 220 В

Сохраните в закладки:

История цены

*История изменения цены! Указанная стоимость возможно, уже изменилось. Проверить текущую цену - >

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-18-2025 | 105446.94 руб. | 110718.59 руб. | 108082 руб. |

| Aug-18-2025 | 104560.4 руб. | 109788.22 руб. | 107174 руб. |

| Jul-18-2025 | 87724.65 руб. | 92110.47 руб. | 89917 руб. |

| Jun-18-2025 | 102788.54 руб. | 107927.42 руб. | 105357.5 руб. |

| May-18-2025 | 89496.28 руб. | 93971.25 руб. | 91733.5 руб. |

| Apr-18-2025 | 101015.80 руб. | 106066.21 руб. | 103540.5 руб. |

| Mar-18-2025 | 100129.10 руб. | 105135.99 руб. | 102632 руб. |

| Feb-18-2025 | 99243.81 руб. | 104205.54 руб. | 101724 руб. |

| Jan-18-2025 | 98357.44 руб. | 103275.87 руб. | 100816 руб. |

Новые товары

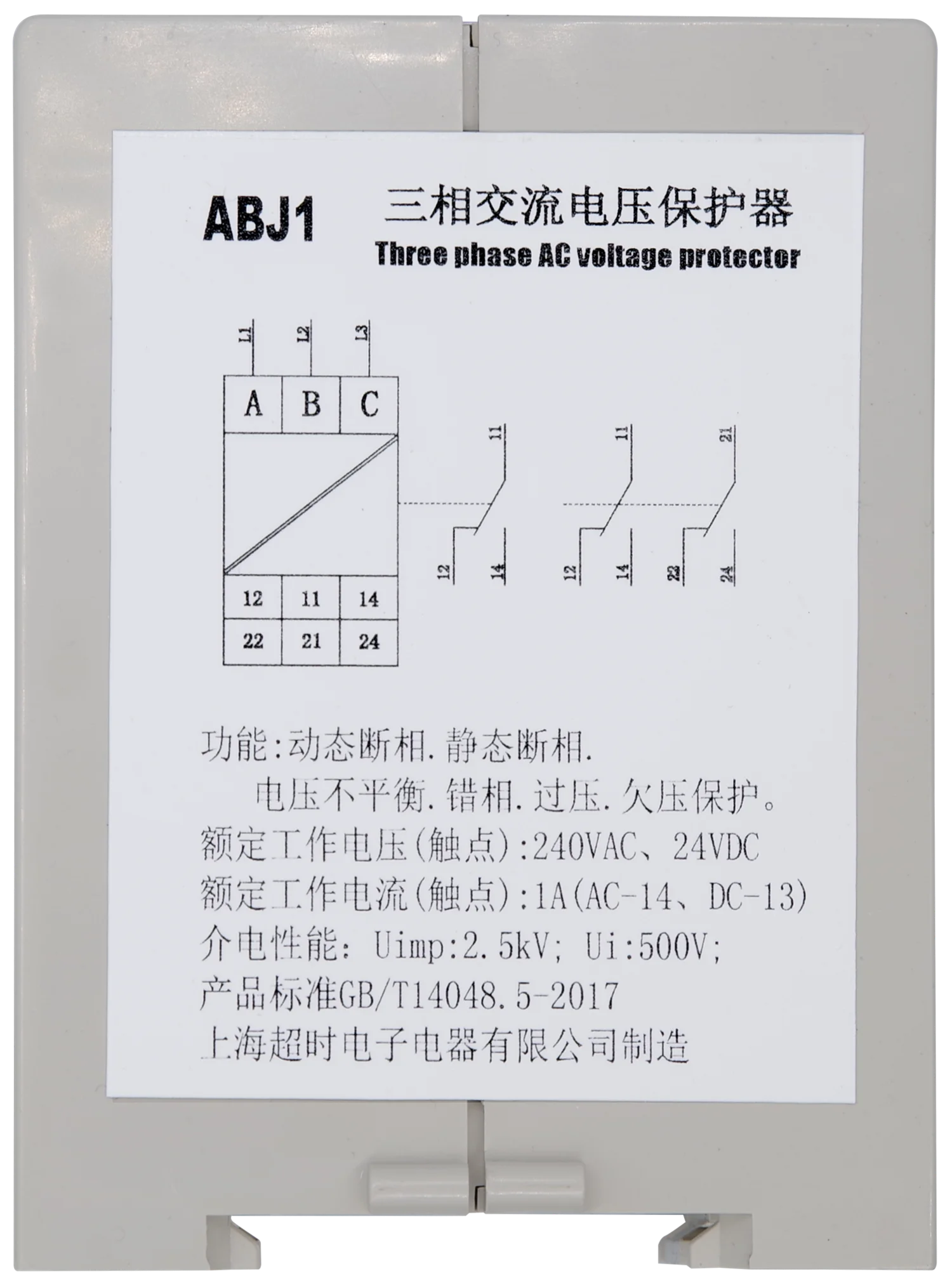

ABJ1 series трехфазный протектор напряжения переменного тока фазная

Однофазный плавный пуск двигателя 220 В 2 кВт 4 6 8 для водяного насоса вентилятора -

Контроллер модуля мягкого пуска двигателя 380 В стартер остановка радиатор

Защита топливного бака Сталь 2 мм АвтоБРОНЯ для Lexus NX 250/Toyota Rav4 (XA50) - купить по

220V Single Phase Motor Soft Starter Module Controller 1KW2KW4KW6KW8KW Online Starting Fan Pump Pressure Reducer Conveyor - купить по

AC 380V 25A 7.5KW интеллигентая (ый) Мотор протектор для плавного пуска двигателя новый -

Смарт-протектор для электродвигателя Acrel серии ARD установочный ток 0 1 ~ 12 A 440 кВт -

Трехфазный контроллер модуля мягкого стартера двигателя 1-22 кВт мягкий стартер

Характеристики

Трехфазный асинхронный двигатель мягкий стартер управления напряжением 220 В

Описание товара

This function can display the firmware version in order to manage the installed equipment group.

Dimensions Dimensions and weight size

Frame size A

weight

Launcher

kilogram

lb

Fanless

5

11.1

With fan (1)

6.2

13.8

Gross weight

7

15.8

Installation and clearance Precautions standard

The Altistart 22 soft starter complies with NEMA ICS1-1 or IEC 60664-1 pollution degree 2 regulations.

For 3 degree environmental pollution, please install a 12 or IP54 cabinet in the Altistart 22 soft starter.

Danger

Danger

Risk of electric shock, explosion or arc

The ATS22 software launcher is an open device and must be installed in a suitable enclosure.

Failure to follow these instructions will result in death or serious injury.

Air circulation

Leave enough free space to help air circulate smoothly from the bottom to the top of the inverter for cooling.

overheat

To avoid overheating the soft starter, please follow the suggestions below:

Install the Altistart 22 soft starter within a vertical range of ± 10 °.

Do not place the Altistart 22 soft starter near heat radiation elements.

Current passing through the Altistart 22 soft starter will cause heat loss, and this heat must be dissipated in the atmosphere around the soft starter. To prevent thermal failure, allow the enclosure to cool down and / or ventilate sufficiently to prevent the ambient temperature around the soft starter from becoming too high.

If multiple soft starters are installed on the control panel, line them up. Soft starters cannot be stacked. The heat dissipated by the bottom soft starter can adversely affect the ambient temperature around the top soft starter.

installation Connection between fan and Altistart 22 soft starter

1 Altistart 22 soft starter 2 fan

Connection and architecture Power terminal Cage

1 Ground connection

Power connection, minimum and maximum wiring capacity, torque

IEC cable

UL cable

Motor power and output

Size / Specification

Minimal

2.5 mm

12 AWG

maximum

16 mm

4 AWG

Torque

Minimal

3 N.M

26.25 lbs.

maximum

3 N.M

26.25 lbs.

Stripping length

10 mm

0.4 inch

Power connection, minimum cross section required for wiring

IEC cable

mm² (Cu 70 ° C / 158 ° F) (1)

UL cable

AWG (Cu 75 ° C / 167 ° F) (1)

2.5

10

230 Vac control, logic input (LI) 24 Vdc, 3-wire control Use line contactor, free stop or controlled stop

230 Vac control, logic input (LI) 24 Vdc, 2-wire control, free stop

Motor delta connection, series connection wiring

The ATS22 soft starter connected to the motor in a delta connection can be connected in series with the motor wiring.

Pay particular attention to the following wiring. Altistart 22 Soft Start-Soft Stop Device User Manual describes this. For details, please contact Schneider Electric.

For 400 V-110 kW motors, the line current is 195 A (rated current with delta connection). The current of each wiring is equal to 195 / 1.5 or 130 A. The constant rated current (ICL) of the selected soft starter is only higher than this current, which determines this rating.

Performance curve Motor thermal protection-cooling curve curve

A Level 10 B Level 20 C Level 30

Trip time for standard applications (level 10)

3.5 ln

32 seconds

Trip time for severe applications (level 20)

3.5 ln

63 seconds

Trip time for severe applications (level 30)

3.5 ln

95 seconds

Motor thermal protection-heating curve curve

A Level 10 B Level 20 C Level 30

Trip time for standard applications (level 10)

3.5 ln

16 seconds

Trip time for severe applications (level 20)

3.5 ln

32 seconds

Trip time for severe applications (level 30)

3.5 ln

48 seconds

main information Product Series Altistart 22 product type Soft starter Product Features Asynchronous motor Application field Pumps and fans Component name ATS22 Grid phase number Phase 3 Rated power supply voltage [Us] 230 ... 440 V-15 ... 10% Motor power (kW) 4 kW 230 V 7.5 kW 400 V 7.5 kW 440 V Factory setting current 14.8 A Power consumption W 39 W for standard applications Use category AC-53A Start type Start with torque control (current limited to 3.5 In) IcL starter rating 17 A for connecting to the motor power cord for standard applications IP protection level IP20 Additional information Assembly method With heat sink Available functions Internal bypass Power supply voltage range 195… 484 V Power supply frequency 50 ... 60 Hz-10 ... 10% Network frequency 45 ... 66 Hz Device connection Use motor power cord to motor triangle terminal Control circuit voltage 230 V-15 ... 10% 50/60 Hz Control circuit energy consumption 20 W Number of discrete outputs 2 Output type Relay output R1 230 V running, warning, trip, stop, not stopped, start, ready C / O Relay output R2 230 V running, warning, trip, stop, not stopped, start, ready C / O Minimum switching current [Imin] 100 mA at 12 V DC (relay output) Switching current 5 A 250 V AC resistive (load) 1 relay output 5 A 30 V DC resistive (load) 1 relay output 2 A 250 V AC inductive load 0.4 20 ms relay output 2 A 30 V DC inductive load 7 ms relay output Number of discrete inputs 3 Digital input type (LI1, LI2, LI3) logic, 5 mA 4.3 kOhm Discrete input voltage 24 V <= 30 V Discrete input logic Positive logic LI1, LI2, LI3 in state 0: <5 V and <= 2 mA in state 1:> 11 V,> = 5 mA Output current 0.4 ... 1 Icl adjustable PTC sensor input 750 Ohm Communication port protocol Modbus Connector type 1 RJ45 Communication data link Serial Physical interface RS485 multipoint connection serial port Transmission rate 4800, 9600 or 19200 bps install equipment 31 Type of protection Phase loss protection: line thermal protection: motor thermal protection: starter Logo CE cooling method Forced ventilation Operating position Vertical direction +/- 10 ° height 265 mm width 130 mm depth 169 mm product weight 7 kg Motor power range AC-3 4… 6 kW at 200… 240 V 3 phases 7… 11 kW at 380… 440 V 3 phases Motor starter type Soft starter surroundings Electromagnetic compatibility Conducted and radiated interference Class A conforms to IEC 60947-4-2 Damped oscillating waves class 3 conforms to IEC 61000-4-12 anti-static interference class 3 conforms to IEC 61000-4-2 is free from electrical transients class 4 conforms to IEC 61000 -4-4 Radiation-free radio frequency electronic interference level 3 according to IEC 61000-4-3 Voltage / current pulse level 3 according to IEC 61000-4-5 Standards compliant EN / IEC 60947-4-2 certified product UL GOST CSA CCC C-Tick Anti-vibration 1 gn (f = 13… 200 Hz) conforming to EN / IEC 60068-2-6 1.5 mm (f = 2… 13 Hz) conforming to EN / IEC 60068-2-6 Impact resistance 15 gn for 11 ms conforming to EN / IEC 60068-2-27 Noise level 45 dB Pollution level Class 2 conforms to IEC 60664-1 Relative humidity 0… 95% without condensation or dripping water conforms to EN / IEC 60068-2-3 Ambient temperature -10… 40 ° C (none) 40… 60 ° C (current derating 2.2% / ° C) Storage temperature -25… 70 ° C Working altitude <= 1000 m none > 1000 ... <2000 m current derating 2.2% / increase 100 m

Трекер стоимости

Отзывы покупателей

Новые отзывы о товарах

ОЧЕНЬ ПЛОХОЙ ПРОДАВЕЦ, НЕ ПОКУПАЙТЕ У НЕГО НИ ЧЕГО . Я С ДУРУ ЗАКАЗАЛ У НЕГО НОЖЬ , ТЕПЕРЬ У... Читать отзыв полностью...

Мошенник. Не покупайте у него. Разводит на деньги.... Читать отзыв полностью...

Магазин №910733027 не советую иметь дело с этим магазином. Чистое кидалово. На запросы не отвечает. Все блокирует... Читать отзыв полностью...

Крестовина сломалась через 15 дней использования. В рекламе указано, что она выдерживает до 400 кг. Я использовал максимум 100 кг).... Читать отзыв полностью...

Не связывайтесь с Wanfeng Factory Store продавец мошейник с декабря 2022 года присылает не действительные трек коды, гоняет по разным... Читать отзыв полностью...

заказала валенки 20.12.22 оплатила , водят за нос последнее прислали липовый трек номер компании СДЭК... Читать отзыв полностью...

добрый день. В чем разница между этими катушками? 071N0051 и 071N0808 - Установлен был 071N0808... Читать отзыв полностью...